Views: 0 Author: Site Editor Publish Time: 2025-09-08 Origin: Site

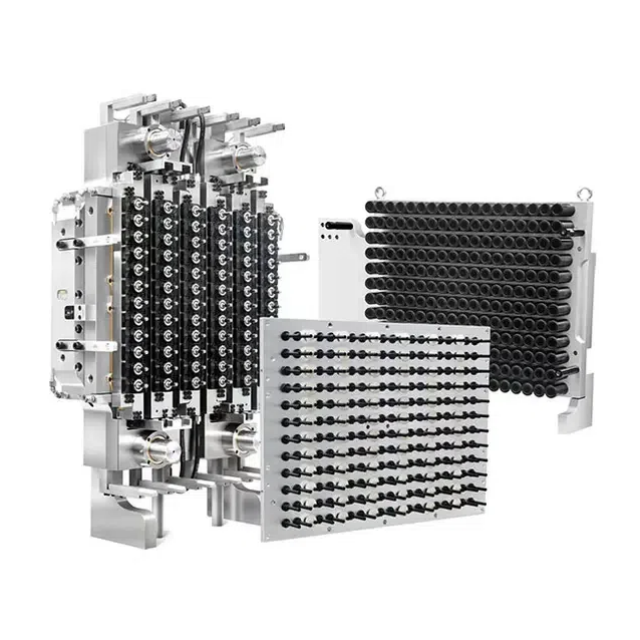

When it comes to the medical packaging industry, ensuring precision, hygiene, and regulatory compliance is non-negotiable. Medical devices, including bottles and vials, require molds that meet stringent standards to guarantee both safety and performance. As a leading manufacturer in precision preform molding, ShuangLi Technology understands these needs and provides state-of-the-art molds tailored for the medical sector. In this article, we will explore the essential aspects of selecting a medical preform mold, including regulatory requirements, critical tolerances, validation processes, and how to choose the right manufacturing partner.

Medical packaging is subject to more rigorous regulatory requirements compared to other industries. These standards ensure that medical products are safe, sterile, and fit for use. When selecting a mold for medical preforms, it is essential to meet hygiene and regulatory criteria, including material compatibility, cleanability, and traceability.

Choosing the right material for the mold is paramount in the medical sector. Stainless steel grades like 304, 316, or specialized medical-grade alloys are commonly used because of their resistance to corrosion, easy cleanability, and longevity. Furthermore, surface finishes play a critical role. Opting for polished or mirror finishes reduces the likelihood of bacterial growth and makes the mold easier to clean, which is crucial for maintaining the sterilization standards required for medical devices.

In medical packaging, traceability is key. Any mold used to produce preforms must come with comprehensive documentation, including material certificates and traceability records. These documents prove that the mold and its components have been manufactured in compliance with medical regulations. Serialization of molds also helps track their use, ensuring that every batch of preforms is accounted for. A reliable supplier will provide clear documentation, making it easier for medical companies to meet regulatory standards and audits.

Precision is critical in medical packaging. Small variations in tolerances can lead to significant issues in functionality and safety. When specifying a mold for medical preforms, it's crucial to consider critical tolerances, particularly those related to the neck finish and sealing surfaces.

The neck finish and sealing surface are crucial for ensuring proper closure and sealing of medical bottles and vials. Tolerances in these areas are typically very tight, often within ±0.05 mm. Even a minor deviation can affect the ability of the cap or closure to seal correctly, leading to leakage or contamination. Therefore, it's vital to choose a preform mold manufacturer who understands the importance of these tolerances and can meet such precise requirements.

Another critical consideration in the design of medical preform molds is the gate and runner system. A poorly designed gate can result in unwanted particles being introduced into the medical preform, which can be harmful when used in pharmaceutical applications. Additionally, stress concentrations created during molding can lead to cracks or defects in the final product. Ensuring that the gate and runner are designed with medical-grade specifications will minimize these risks and ensure the mold meets the necessary standards.

The validation process for medical preform molds is an essential step in the manufacturing process. Suppliers should provide comprehensive validation and testing to demonstrate the mold's reliability and compliance with medical standards.

A reputable medical preform mold supplier will perform sample batch tests to ensure the mold produces consistent and reliable results. Dimensional reports should be provided to verify that the preforms meet the required specifications. Additionally, bioburden and cleaning validation notes are necessary to prove that the mold can be properly sterilized and is free from contaminants, ensuring the safety of the final product.

Beyond the initial testing phase, ongoing maintenance and quality assurance are critical. Suppliers should maintain detailed logs of mold maintenance and repairs, along with non-conformance reports for any deviations from the set specifications. Change controls are also vital to ensure that any modifications to the mold design or manufacturing process do not compromise the mold's performance or compliance.

Once the mold has been validated, it is essential to ensure that it is ready for mass production. This stage includes conducting pilot runs and scale-up testing to ensure that the mold can handle the demands of high-volume production.

Trial molding is an essential step before full-scale production. This phase helps identify potential issues in the mold design or manufacturing process that may not have been apparent during the initial testing phase. Acceptance criteria for trial molding typically include sample retention, dimensional accuracy, and destructive testing to evaluate the mold's performance under real-world conditions. These trials ensure that the mold will consistently produce high-quality preforms.

To achieve repeatable and reliable results, it's crucial to match the mold to the injection molding machine. Factors like clamping force and shot size must be carefully considered to ensure the mold performs optimally during mass production. A mismatch can lead to defects or inconsistencies in the final product, which is why it's essential to work with a supplier who understands the intricacies of machine and mold compatibility.

Selecting the right manufacturing partner for your medical preform mold is a critical decision. The right supplier will help you navigate regulatory requirements, ensure high-quality production, and deliver excellent after-sales support.

One of the first things to look for in a supplier is relevant certifications. ISO 13485 certification is an essential standard for medical device manufacturers, demonstrating that the supplier adheres to the highest quality management standards for medical products. Cleanroom capabilities are also crucial for ensuring that the mold is produced in a contamination-free environment. Additionally, experience working with past pharmaceutical customers is a good indicator of the supplier’s ability to meet the specific needs of the medical packaging industry.

Medical preform molds are subject to wear and tear over time, so after-sales support is critical. A good supplier will provide rapid repair services and offer spare cores to minimize downtime and ensure continuous production. This is particularly important in industries like pharmaceuticals, where delays can have significant consequences.

Choosing the right medical preform mold requires a thorough understanding of the industry’s precise requirements, including regulatory standards, critical tolerances, and production readiness. ShuangLi Technology, with its advanced equipment and focus on quality, provides the expertise necessary to meet these needs. By selecting the right mold and supplier, you ensure that your medical packaging not only complies with stringent regulations but also meets the high standards required for safe and effective medical products. If you're looking for high-quality medical preform molds that meet all necessary criteria, contact us today to learn more.