| Availability: | |

|---|---|

| Quantity: | |

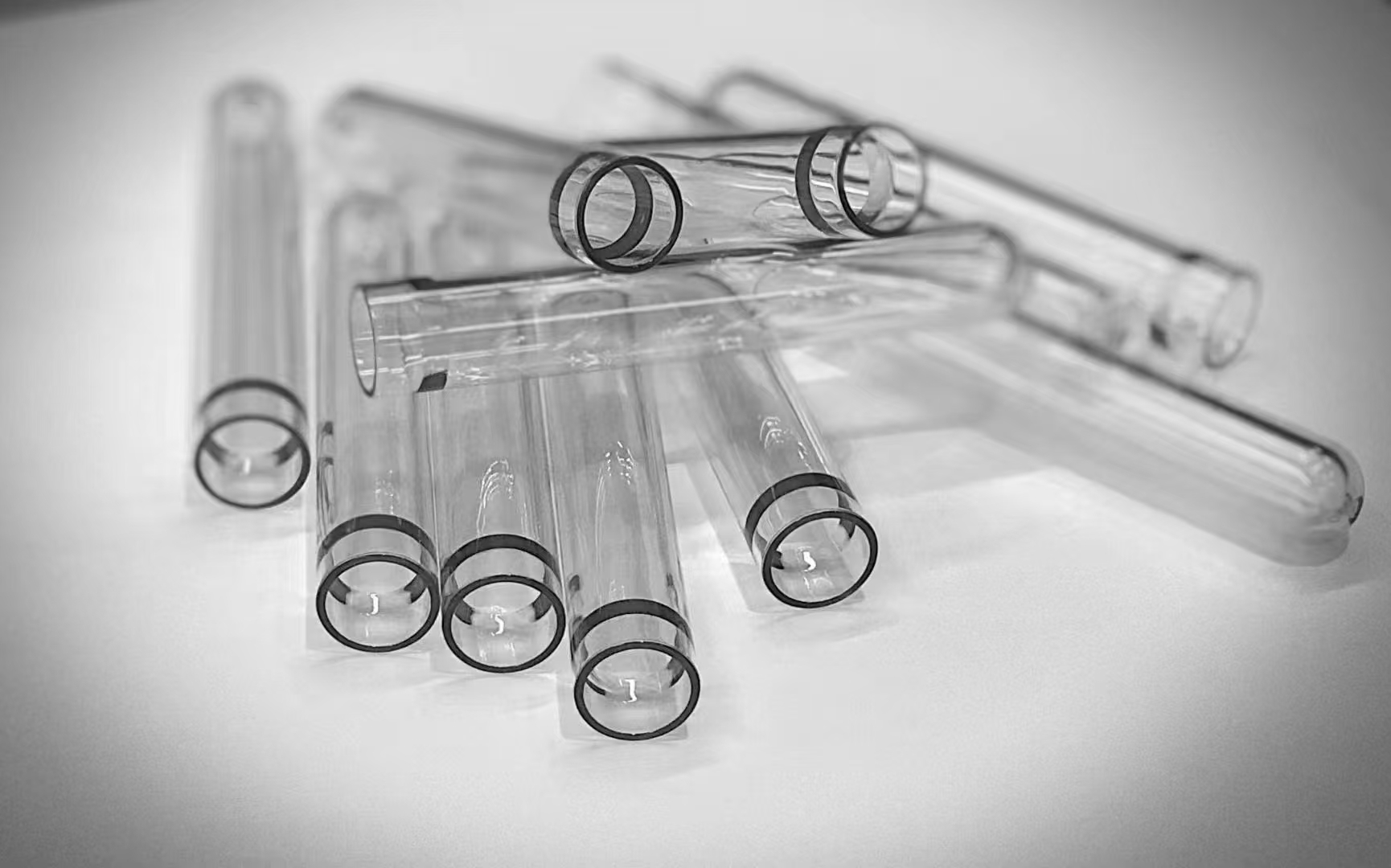

316L Stainless Steel Prefabricated Tube Blanks are premium semi-finished components designed to excel in harsh, corrosive environments where material integrity is non-negotiable. Crafted from high-quality 316L stainless steel, these prefabricated tube blanks offer unmatched corrosion resistance, high-purity performance, and dimensional precision—making them the top choice for critical applications across industries. Whether used in pharmaceutical processing, marine engineering, or chemical manufacturing, they are engineered to deliver reliable performance in the most demanding conditions. The low carbon content and enhanced alloy composition of these 316L tube blanks ensure they maintain structural integrity even after welding and exposure to extreme temperatures, providing long-lasting value and peace of mind.

The advanced alloy composition of 316L Stainless Steel Prefabricated Tube Blanks—including enhanced molybdenum and low carbon—delivers exceptional resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking. This makes them ideal for environments with saltwater, chemicals, or corrosive gases. Unlike standard stainless steel grades, these tube blanks maintain corrosion resistance even with prolonged exposure to harsh substances, ensuring critical systems remain leak-free and operational.

These 316L tube blanks feature an electropolished surface finish that achieves exceptional purity, meeting strict cleanliness standards for pharmaceutical, biotech, and high-precision industrial applications. The smooth, non-porous surface eliminates particle accumulation and bacterial growth, preventing contamination of fluids or materials passing through. This high-purity finish is essential for industries where product quality and regulatory compliance are paramount.

Manufactured using cold-drawing techniques, these prefabricated tube blanks offer outstanding dimensional precision—with consistent outer diameter and wall thickness. This precision ensures seamless integration into existing systems and enables leak-free orbital welding, critical for high-pressure and high-purity applications. Uniform dimensions also simplify installation, reducing error risks and ensuring systems perform as intended.

316L Stainless Steel Tube Blanks maintain mechanical properties across a broad temperature range—from cryogenic conditions to high-heat environments. This temperature stability makes them suitable for diverse applications, including cryogenic storage systems and high-temperature processing equipment.

In the pharmaceutical industry, these 316L Stainless Steel Prefabricated Tube Blanks are used in pure water systems, active pharmaceutical ingredient (API) manufacturing, and bioreactor pipelines. Their high-purity finish and corrosion resistance ensure compliance with strict regulations like ASME BPE and cGMP. The tube blanks prevent pharmaceutical product contamination, supporting the production of safe, effective drugs. They are also suitable for sterile processing environments where cleanliness and reliability are essential.

For marine engineering projects, these 316L tube blanks are ideal for seawater desalination plants, offshore platform piping, and shipboard condensate systems. Their resistance to saltwater corrosion and chloride-induced stress cracking lets them withstand the harsh marine environment, providing long-lasting performance for offshore structures. This durability reduces maintenance costs and downtime, making them a cost-effective choice for marine applications.

In chemical processing plants and refineries, these prefabricated tube blanks construct pipelines for transporting aggressive chemicals like sulfuric acid, sodium hydroxide, and organic solvents. Their corrosion resistance and chemical compatibility ensure pipelines remain intact and safe—even when exposed to harsh substances. They are also suitable for high-pressure and high-temperature chemical processing systems where reliability and safety are critical.

Our 316L Stainless Steel Prefabricated Tube Blanks are manufactured from ASTM A270 316L stainless steel, ensuring consistent quality and performance. Each batch includes a third-party mill test certificate (MTC) detailing chemical composition, mechanical properties, and non-destructive test results. This certification verifies compliance with the highest industry standards, giving you confidence in product quality and reliability.

Our team of experienced metallurgical engineers provides dedicated technical support to help you select the right 316L tube blanks for your application. We offer guidance on material selection, installation, and maintenance, ensuring you maximize product value. Whether you need welding advice or failure analysis assistance, our technical team supports you throughout the product lifecycle.

We understand every application has unique requirements, so we offer customization for our prefabricated tube blanks. We tailor dimensions, surface finish, and length to meet your specific needs, ensuring a perfect fit for your systems. Our flexible manufacturing process accommodates small and large orders, providing customized solutions that align with your project requirements and budget.

A: The key difference is carbon content. 316L Stainless Steel Prefabricated Tube Blanks have lower carbon content, preventing carbide precipitation during welding. This makes them more suitable for sensitized environments where post-welding corrosion resistance is critical.

A: Yes, these 316L tube blanks undergo solution annealing as a standard heat treatment to optimize corrosion resistance. Austenitic stainless steels like 316L do not require age-hardening, as solution annealing provides the best balance of strength and corrosion resistance.

A: Yes, every batch of our 316L Stainless Steel Prefabricated Tube Blanks includes a third-party MTC. This certificate details chemical composition, mechanical properties, and results of non-destructive tests like PMI, UT, and ET.

A: Yes, the exceptional dimensional precision and structural integrity of these prefabricated tube blanks make them suitable for high-pressure applications. Their uniform wall thickness and leak-free welding capabilities let them withstand pressures in chemical processing, marine engineering, and other high-pressure systems.