| Availability: | |

|---|---|

| Quantity: | |

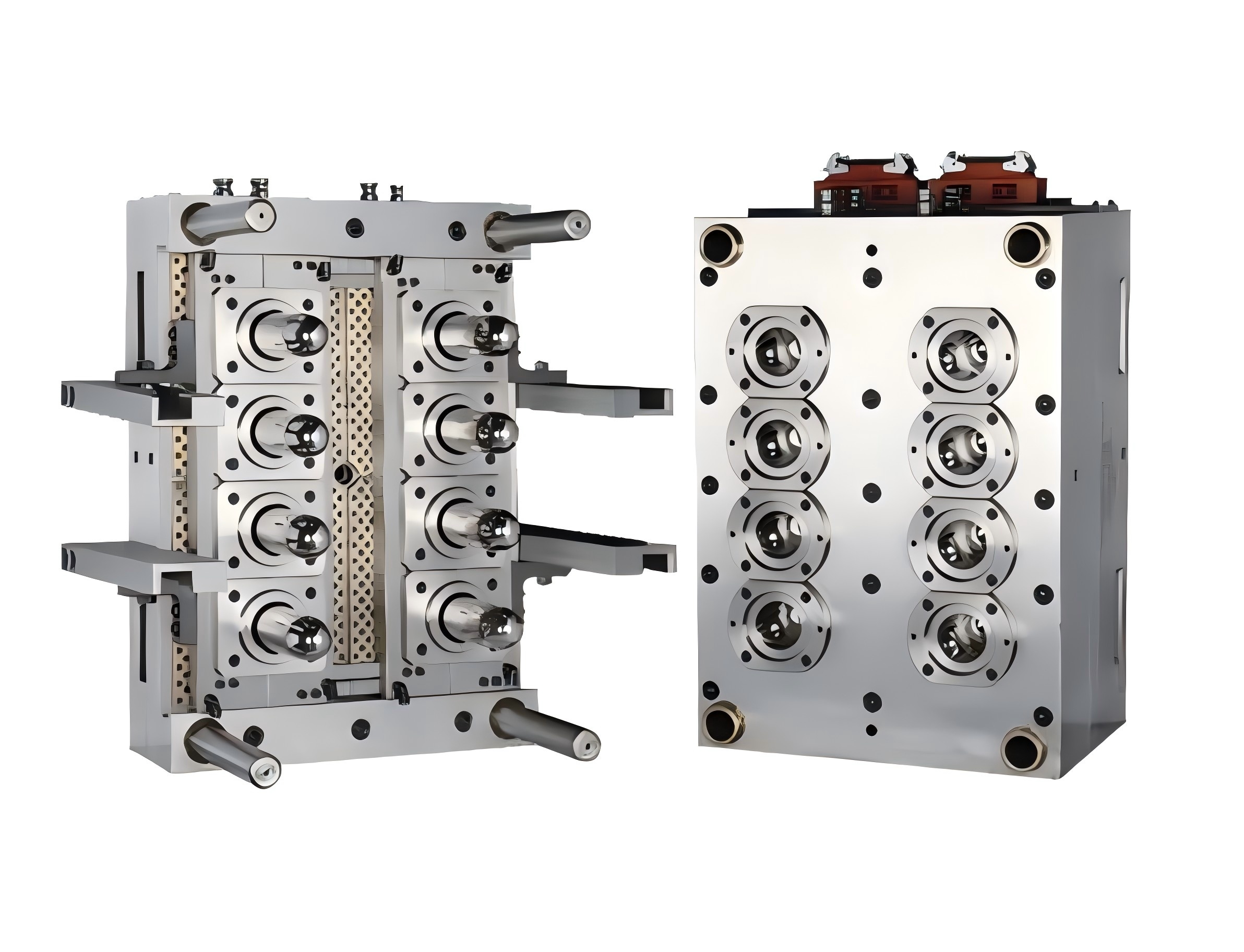

These molds leverage standardized base structures and modular components, combined with customizable cavities to meet specific part requirements. Constructed from premium tool steels (H13, S7) or aluminum alloys, they are designed for rapid cycle times and prolonged use, withstanding up to 1 million injection cycles without performance degradation.

Featuring multi-cavity designs (ranging from 8 to 96 cavities), these molds include pre-installed hot runner systems, cooling channels, and ejection mechanisms optimized for high-speed production. Advanced CAD/CAM technology ensures precise cavity geometry, while CAE simulations predict melt flow and cooling behavior to eliminate defects like warpage and short shots.

High-Speed Performance: Hot runner systems reduce material waste and cycle times by 30%, enabling production rates of up to 120 shots per hour for small components.

Modular Cavity Design: Interchangeable cavity inserts allow quick product switching, minimizing downtime during SKU changes in multi-product facilities.

Precision Cooling System: Strategically placed baffle and conformal cooling channels ensure uniform temperature distribution, reducing part cooling time by 20%.

Wear-Resistant Coatings: PVD titanium nitride (TiN) coatings on critical components extend mold life by 50% in abrasive material applications (e.g., filled PP, glass-reinforced nylon).

Automation-Ready: Designed for compatibility with robotic part removal and automated sprue pickers, enhancing integration with Industry 4.0 manufacturing lines.

Consumer Electronics: Multi-cavity molds for smartphone cases (24-cavity) and laptop keyboard frames, producing 50,000+ parts daily with 0.05mm wall thickness precision.

Packaging Industry: 64-cavity molds for caps and closures, featuring anti-stick coatings for seamless ejection of PE and PP components.

Automotive Components: Large-scale molds for interior trims and electrical connectors, capable of processing high-temperature materials like PEEK and PPS.

Household Appliances: 32-cavity molds for washing machine knobs and refrigerator shelves, ensuring consistent surface finishes (Ra ≤ 0.2μm) for aesthetic parts.

Medical Devices: Cleanroom-compatible molds for syringes and IV connectors, constructed from electropolished stainless steel to meet ISO 13485 standards.

Q: What is the typical cycle time for high-volume molds?

A: Cycle times range from 5-30 seconds, depending on part size and material, with hot runner systems reducing solidification time significantly.

Q: Can these molds handle engineering plastics like nylon and ABS?

A: Yes, our molds are heat-treated and coated to process all thermoplastics, including filled and reinforced materials.

Q: How do you ensure cavity-to-cavity consistency?

A: Each cavity is machined using CNC milling with 0.005mm tolerance and individually inspected with CMM to guarantee uniform performance.

Q: Do you offer mold maintenance programs?

A: Yes, we provide preventive maintenance packages including lubrication, wear part replacement, and performance audits to maximize mold lifespan.

Q: What is the maximum part size these molds can produce?

A: Standard molds accommodate parts up to 300mm x 200mm x 150mm, with custom designs available for larger components.