| Availability: | |

|---|---|

| Quantity: | |

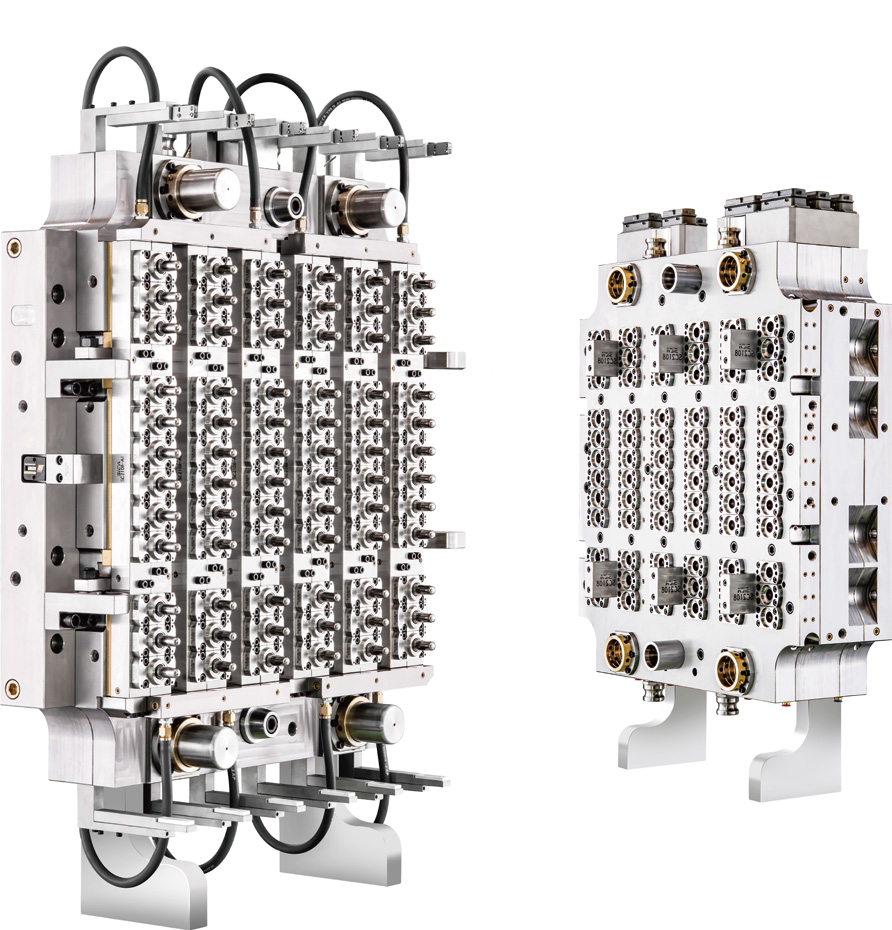

Semi-finished Prefabricated Molds are innovative mold systems that bridge the gap between ready-to-use solutions and fully custom designs, engineered to simplify manufacturing workflows and eliminate the inefficiencies of traditional custom mold development. These molds are built with pre-engineered, standardized components and robust structures, while retaining the flexibility to adapt to specific product requirements across diverse industries. Available in key types including injection molds, die-casting molds, and blow molds, they are crafted from premium materials such as H13 tool steel, aluminum alloy, and high-performance engineering plastics—ensuring reliable performance even in demanding production settings. Each mold comes equipped with pre-machined cavities, cores, and ejection systems, with the option to integrate custom inserts or adjust gating systems to match unique product geometries. Whether for low-volume prototyping or high-speed mass production, these molds are optimized to deliver consistent results, supported by advanced CAD modeling and simulation tools that refine design precision before manufacturing begins.

The foundation of Semi-finished Prefabricated Molds lies in their industry-proven standardized design, which incorporates essential components like guide rails and water channels to ensure compatibility and performance. Unlike rigid off-the-shelf molds, they offer extensive customization: clients can tailor cavity shapes, ejection mechanisms, and surface textures to align with their product’s functional and aesthetic needs, making them versatile for a wide range of applications.

By leveraging pre-existing design frameworks and pre-machined bases, Semi-finished Prefabricated Molds drastically reduce lead times compared to fully custom projects. This rapid deployment is a game-changer for businesses launching time-sensitive products, allowing them to accelerate time-to-market and stay ahead of competitors without sacrificing quality.

Every Semi-finished Prefabricated Mold undergoes rigorous heat treatment to enhance hardness and durability, ensuring it can withstand the rigors of continuous production. Precision machining guarantees tight tolerances for cavity dimensions, resulting in consistent part quality and minimizing waste from misaligned or imperfect components.

The modular design of these molds—featuring replaceable inserts and interchangeable components—allows for easy modifications when product iterations are needed. This adaptability extends the mold’s lifecycle, reducing long-term costs by eliminating the need to invest in entirely new molds for product updates or variations.

Injection molds under the semi-finished prefabricated line are ideal for producing consumer goods such as household appliances, packaging containers, and electronic enclosures. Their precision and customization capabilities ensure that plastic parts meet strict design specifications, from intricate details to smooth surface finishes.

Die-casting molds are engineered to handle high-temperature molten metals, making them perfect for manufacturing automotive parts like engine brackets and transmission components. The durable materials and robust construction of these molds ensure they can withstand the thermal stress of die-casting processes while maintaining dimensional accuracy.

Blow molds in this range are designed for creating hollow plastic products, including bottles, fuel tanks, and industrial drums. They support multi-layer structures, enabling the production of containers with specialized properties such as barrier protection or enhanced strength.

Prefabricated rubber molding solutions are tailored for manufacturing seals, gaskets, and O-rings. Equipped with anti-adhesive coatings, these molds facilitate easy part release, reducing production downtime and ensuring consistent quality for critical sealing components.

For aerospace and marine industries, composite molding molds—built for carbon fiber and fiberglass materials—are designed to withstand high-pressure autoclave processes. Their durability and precision make them suitable for producing lightweight, high-strength components used in aircraft and marine vessels.

A: Yes, the modular design of our Semi-finished Prefabricated Molds allows for easy adjustments to cavities, cores, and gating systems. This flexibility makes them ideal for product variations or updates, eliminating the need for entirely new mold investments.

A: We offer a range of surface finishes to suit different applications, from ultra-polished surfaces for optical components to textured finishes (such as leather grain or matte) for aesthetic parts. Each finish is applied with precision to meet your product’s functional or visual requirements.

A: Absolutely. Our Semi-finished Prefabricated Molds are available in single-cavity designs for low-volume prototyping and multi-cavity designs optimized for high-speed mass production. This versatility ensures they can adapt to your production volume needs as your business grows.

A: Yes, our technical team offers end-to-end support, including mold setup, trial runs, and ongoing maintenance. We work closely with your team to ensure the mold integrates seamlessly with your production equipment and resolve any issues promptly to minimize downtime.

A: Our Semi-finished Prefabricated Molds meet the same high-quality standards as fully custom molds. They undergo rigorous testing and precision machining, with premium materials and heat treatment to ensure durability and performance—all while offering cost and time savings.